Cycling hot air and realizing high heat utilization ratio, the asphalt smoke is recycled to the drying drum again, and the emission of harmful gas is very small. The hot mix plant recycling has high feeding rate of recycled asphalt, up to 50-100%.

Capacity: 120-320T/H

Delivery: 45 days

Warranty: 13 months

Equipment highlights: Module installation, stable output, Siemens electronic control, fully automatic computer operation

.jpg)

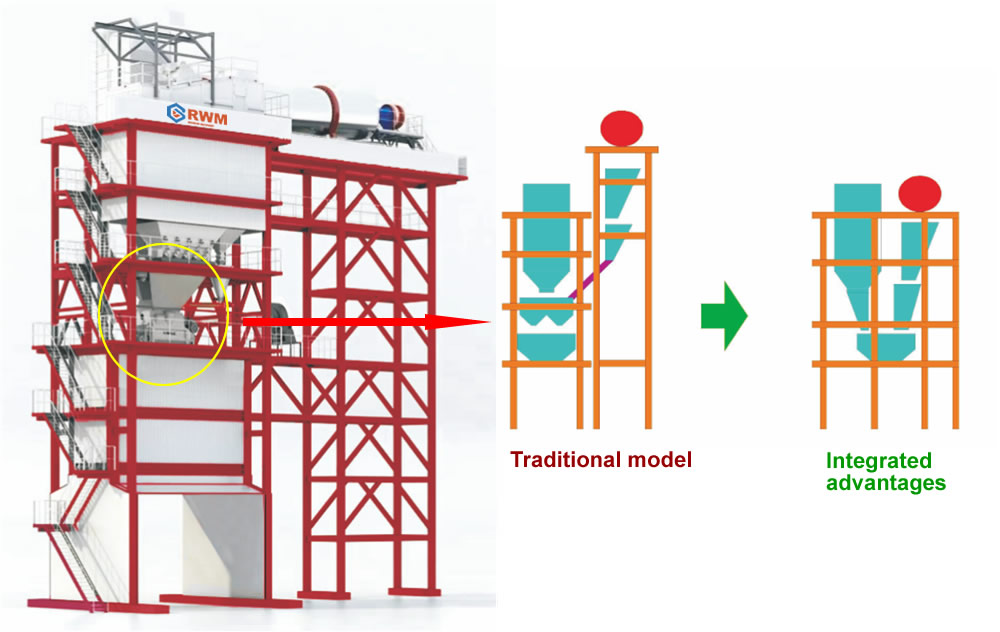

1. The integrated design of the mixing plant integrates the regeneration plant into the original equipment. The overall modular installation is fast, saving 40% of the installation period compared with the traditional regeneration.

2. Larger working space in the main building, which can be equipped with a variety of admixture scales under loose maintenance.

3. The total height of the equipment is reduced, which is 3M lower than that of conventional asphalt mixing plant + recycled equipment. The vibrating screen and recycled drum platform are connected to ensure safe and convenient maintenance.

4. The mixer is repositioned to realize regenerative unloading without chute and no trouble of sticking materials in chute. The unloading speed of regeneration is 50% higher than that of ordinary regeneration, which is more suitable for rapid production.

| Model | RLB1500 | RLB2000 | RLB3000 | RLB4000 | |

| Production capacity standard condition | 120T/H | 160T/H | 240T/H | 320T/H | |

| Machine power | 450KW | 580KW | 715KW | 830KW | |

| Mixer production capacity | 1500kg/batch | 2000kg/batch | 3000kg/batch | 4000kg/batch | |

| Dust removal area (m2) | 510 | 680 | 924 | 1300 | |

| Blending ratio (%) | 40 | 40 | 33 | 25 | |

| Fuel consumption (kg/t finished material) |

≤5.5-7.0 | ||||

| Flue gas emission concentration (mg/Nm3) | ≤50 | ||||

| Ambient noise (Db) | ≤80 | ||||

| Metrological accuracy | Static | Primary aggregate ≤±0.5% Powder: ≤±0.5% Asphalt ≤±0.25% Recycled ≤±0.5% Additive ≤±0.2 % | |||

| Dynamic | Primary aggregate ≤±2.0% Powder: ≤±2.0 % Asphalt ≤±1.5% Recycled ≤±2% Additive ≤±1.0% | ||||

| Control system | Dual computer and dual control, production system + Dual industrial computer | ||||

| ITEM | Advantages |

| Structural design | The integrated design of the mixing plant integrates the regeneration plant into the original equipment. The overall modular rapid installation saves 50% of the installation period compared with the traditional regeneration. |

| Part configuration | All pneumatic and reducer components of international brands are of good quality. |

| Burner | Special burner for imported asphalt station, with fuel consumption of 5.8kg/t under standard conditions, energy saving and emission reduction, and promoting production. |

| Vibrating screen | The vibration motor is fully enclosed, simple in structure, dustproof, maintenance free and low in maintenance cost. |

| Mixer | There are recycled materials, SMA manual feeding port and modified asphalt plus fiber interface on the host to meet the later upgrading. The mixing lining plate blade adopts high wear resistance, stability and durability and long service life. |

| Electric control system | Dual industrial host and dual system control ensure the continuous progress of the production process and reduce the shutdown, waste products and possible accidents caused by computer failure. |

One set of RWM- Asphalt Mixing and Recycling Plant

Asphalt Mixing Plant LBJ1000 export to Russia

Asphalt Mixing Plant LBJ3000 Installing in Malaysi